Top 18 Best Carpenter Square Features, Reviews, and FAQs

Brandon Forder May 12, 2024 3:58 PM

To ensure success in any design or building project, precise measurements are essential. Incorrect measurements can necessitate a complete rebuild, which is expensive in terms of both time and money. Therefore, architects, carpenters, and civil engineers favor using a framing square to eliminate the possibility of making such errors. The precise measures required for a wide range of tasks need the usage of framing squares, which necessitate flawless gradations. Although these hand tools may appear complicated to use at first appearance, you will find that they are actually rather simple and will prove invaluable to your design efforts. There are a lot of framing squares out there, so finding the right one might be challenging. In order to assist you in making a well-informed selection, we have analyzed the top framing squares of 2022 and compiled a detailed buying guide.

Compare Products

- SCORE9.6

- BrandSwanson Tool Co., Inc

- Prime

- SCORE9.4

- BrandIrwin Tools

- Prime

- SCORE9.0

- BrandMr. Pen

- Prime

- SCORE9.0

- BrandJohnson

- Prime

- SCORE9.0

- BrandJohnson

- Prime

Last update on 2024-05-12 / Affiliate links / Images, Product Titles, and Product Highlights from Amazon Product Advertising API

Types

The most popular choices are shown below.

Try square

It is a device for determining angles of 90 degrees, sometimes known as a tri-square. It ensures that things are square to one another, as the name says. A metal blade and wooden handle are the standard components of this tool.

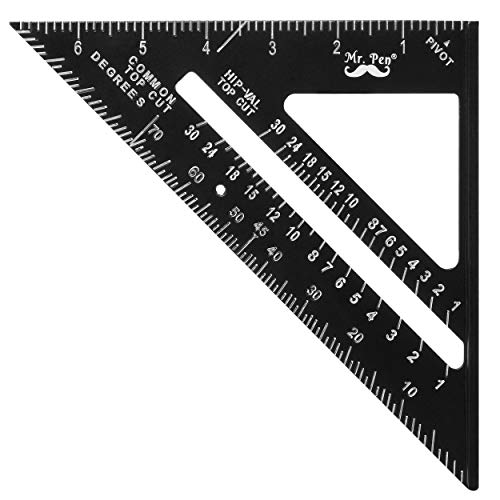

Speed square

The Speed square, sometimes known as a rafter square, is a triangular instrument. While the Swanson Tool Company has trademarked the word "Speed square," the term is more often used. For the woodworker, it combines the functions of a ruler, T-edge, and numerous angles into one convenient tool.

Framing square

This instrument is L-shaped and somewhat larger than a standard try square. It's useful for creating straight lines and square corners. You can use the framing square for anything from constructing picture frames to installing rafters in your roof.

Combination square

The anvil is affixed to the end of a straight ruler, creating a multipurpose instrument. The anvil has two faces, one of which is flat and the other, known as the shoulder, is inclined. It can be slid to make the required perpendicular lines and can even retain an angle's form and size for simple conversion of measurements.

Double square

Angles of 90 degrees can be measured with a double square. In contrast to the combination square, this head has two parallel sides. The movable joint in the head is ideal for setting repeatable angles in a regular grid.

Build material

The quality and precision of a framing square are directly related to the materials with which it is built. To create framing squares that consistently outperform the competition, most producers use on high-quality metals like stainless steel, carbon steel, and aluminum. If you choose stainless steel, though, you'll need to take extra precautions to prevent corrosion and oxidation damage.

Accuracy

The accuracy of the frame square is the most crucial factor to consider. Incorrect measurements and other problems can arise from using a tool that isn't up to par. Put a frame square next to a ruler and compare the two to see if it is accurate. If they coincide, you can use the square to determine if a line is straight by drawing it.

Readability

It is useless to have a frame square if you can't read the graduations on it. The legibility of a framing square is essential for its use and will help avoid mistakes. It is common practice for manufacturers to permanently mark framing squares using a stamp or a laser. Markings should be a color that stands out against the background of the framing square.

Durability

For a framing square to be useful, it must be constructed with high-quality materials and finish work after several uses. Framing squares' longevity is determined by their build material and the precision of their markings. When subjected to intense force, flimsy materials might crack or flex, resulting in inaccurate readings. Further, the scale is useless if the markings on it fade after a few months.

Graduations reflect on your measurements

The intervals between the various scale readings on a square are called "graduations." Each scale has its own unique set of graduations that influence the level of accuracy you may achieve. Carpenters typically favor 1/8-inch graduations. Still, choices exist that provide much more granularity, such as 1/10 inch, 1/12 inch, and beyond.

Tables and conversions ease up calculations

Infuriatingly so, if calculations midway through a job cause delay and hassle. Reduce the amount of time it takes to find answers to problems involving complex computations, conversions, and tables over a large area. In any framing square, the engravings of the Essex board and rafter tables are indispensable.

Body and tongue’s scale outlook

The specifics of your job are directly related to the length of the body and tongue of an L-square. An understanding of how different arm types affect the accuracy of a square ruler is helpful for everyone, but especially a beginner. Despite their pinpoint accuracy, thinner scale blades are easily dislodged by even moderate force. Alternatively, blades with a greater thickness tend to stay put and keep a high degree of precision.

How can I know the measurement system of a framing square?

A framing square's description box will tell you what system of measurement it uses. If you want to make the most of the instrument, it's a good idea to see if it comes with conversion tables.

Should I buy a framing square made of stainless steel or aluminum?

Aluminum frame squares are the best option because of their lightweight durability. Rusting and oxidation can weaken stainless steel, reducing its durability.

What are tapered framing squares like?

Antique frame squares have a tapered shape. Squares used to be thicker all the way through, and they often had mills on the edges and removable fences. Square rulers wouldn't get lost so easily with this design, and they're still useful and accurate today.

Are framing squares trustworthy for squaring?

Yes! The arms of a framing square are always at 90 degrees to guarantee a squared frame. On the other hand, a square ruler can only reach as far as its arms will allow to guarantee a subject's square measurements when working on larger boards or walls. Its reach is limited, therefore it is useless if you try to use it elsewhere.

How many variations on a simple tool there are for carpenter squares is truly astounding. It's important to keep in mind that the accuracy and precision of your next job depend on the carpenter square you use, so it's worth your time to shop around for one that meets your needs.